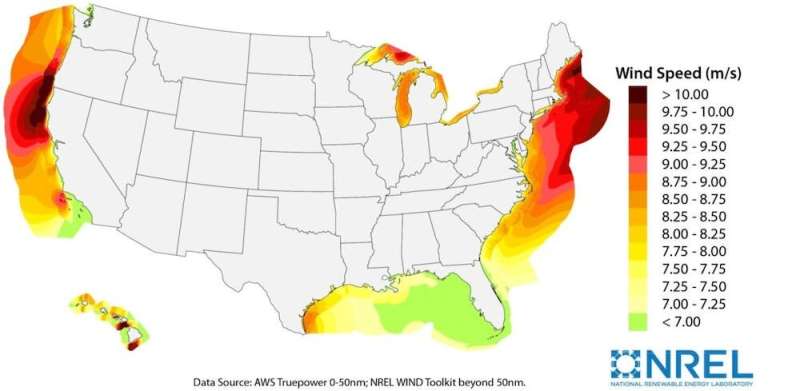

With some of the strongest coastal winds in the United States, Northern California has a huge potential to provide sustainable energy. However, it also has a drawback. Due to the abrupt drop-off of its international shelf, building conventional wind turbines directly on the seafloor is expensive, if not impossible.

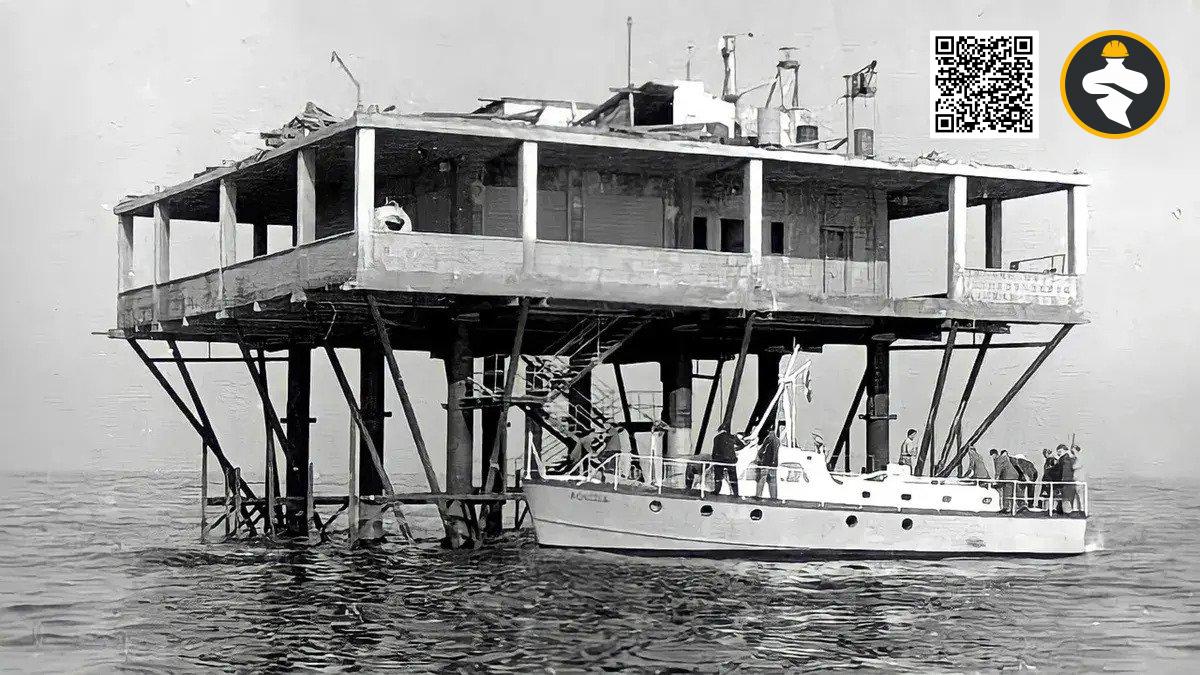

These “monopile” buildings are largely impossible if the water depth reaches 200 bases, or around the height of an 18-story building. A solution has been found and is currently being tried in numerous locations worldwide for floating wind turbines.

California is advancing with a plan to create the first floating coastal wind farms in the country because failure has placed pressure on the hydroelectric industry. The federal government auctioned off five parcels of land on December 7, 2022, to businesses with plans to build floating wind farms 20 long hauls off the coast of California. The flings, which collectively exceeded US$ 757 million, were lower than recent plats off the Atlantic seacoast, where wind granges can be moored to the seafloor. How do floating wind farms operate then?

How to float a turbine?

Similar to other wind turbines, a floating wind turbine generates power as wind pushes against its blades, turning the rotor. However, a floating wind turbine sits on a platform with mooring lines, such as chains or ropes, that connect to anchors in the seabed below, as opposed to having its tower implanted directly into the ground or the seafloor.

The turbine is secured by these mooring lines against the wind and is kept linked to the cable that sends its electricity back to land. The floating platform alone provides the majority of the stability. The trick is to create a platform that prevents the turbine from toppling excessively during storms or heavy winds.

There are three main types of platforms:

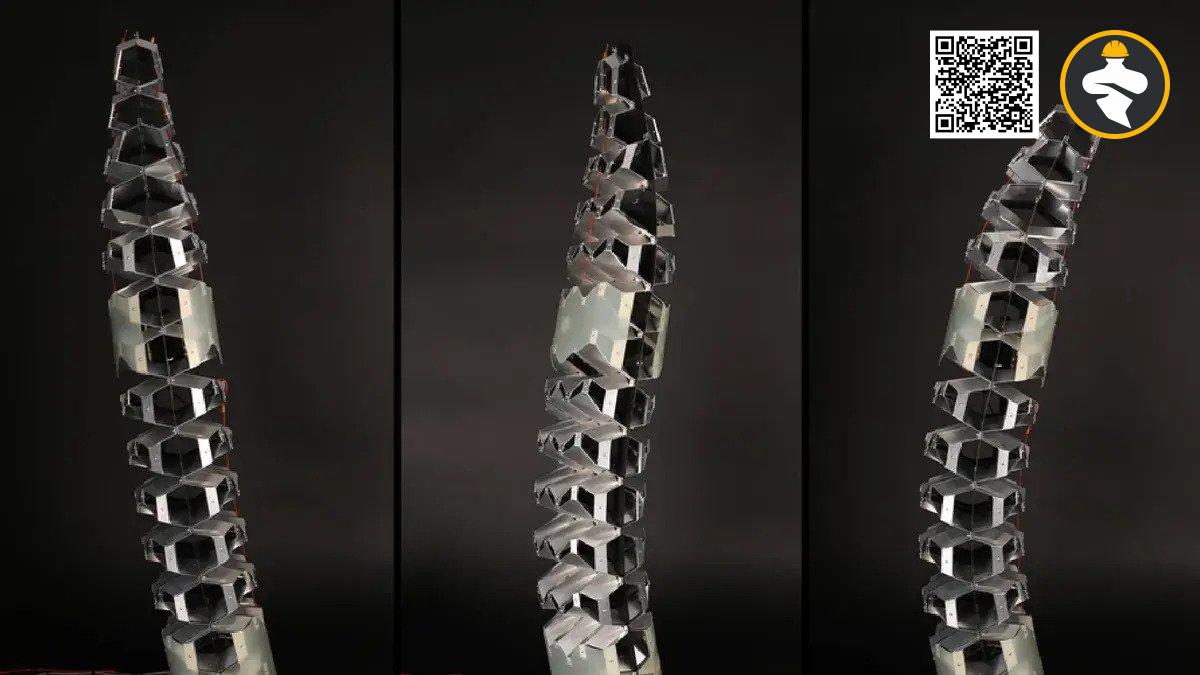

- A long hollow cylinder that descends from the turbine tower is known as a spar buoy platform. It is weighted with ballast in the bottom of the cylinder to reduce its center of gravity, and it floats vertically in deep water. Then, to prevent damage, it is fixed in place with slack lines that allow it to float with the water. For years, the oil and gas sector has used spar buoys for its offshore operations.

- Large floating hulls that extend from the tower on semisubmersible platforms are also secured to prevent drifting. On several of these hulls, designers have started experimenting with numerous turbines.

- Platforms with tension legs have smaller platforms and taut lines that extend downward to the floor. These are lighter, but because they rely more on mooring lines and anchors for stability, they are more susceptible to earthquakes and tsunamis.

While the turbine is running, each platform must sustain the weight of the turbine and maintain stability. This is made possible in part by the hollow platform, which is frequently constructed of substantial steel or concrete structures and acts as buoyancy for the turbine. In comparison to fixed-bottom structures, which need specialized vessels for installation on site, some can be entirely assembled in port and towed out for installation, making them potentially much more affordable.

Wind turbines that can generate 10 megawatts or more of power can be supported on floating platforms; this is several times more power than the usual onshore wind turbine you could see in a field, and their size is comparable to other offshore wind turbines.

Why do we need floating turbines?

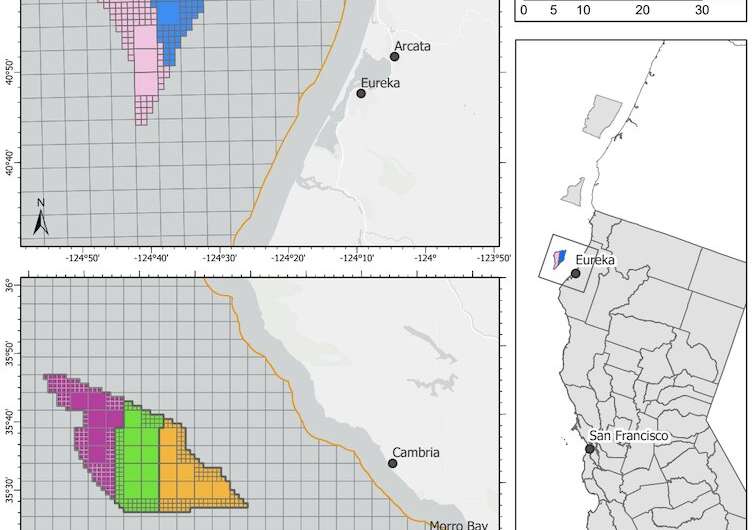

Some of the strongest wind resources are found far from land in areas with hundreds of feet of water below, such as off the coasts of Japan, the Mediterranean Sea, the Great Lakes, and the United States. The 583 square miles of U.S. lease areas that were auctioned off in early December span two sites: one off the coast of Morro Bay in central California and the other close to the Oregon state boundary. Any wind farm that is even a few miles from coast will require floating turbines since the water off California quickly becomes deep.

According to government estimates, wind farms in those five regions if constructed could produce approximately 4.6 gigawatts of renewable electricity, sufficient to power 1.5 million homes. The winning businesses said they could generate much more energy. But it will take time to actually put windmills on the river. The Justice Department’s anti-trust review will be followed by a protracted planning, regulatory, and environmental review process that generally lasts many years for the lease auction winners.

Around the world, there are a number of full-scale demonstration projects with floating wind turbines running in Asia and Europe. The Hywind Scotland project, which has five 6-megawatt turbines supported by spar buoys created by the Norwegian energy company Equinor, became the first commercial-scale offshore floating wind farm in 2017.

One of the winning bids came from Equinor Wind US in Central California. RWE Offshore Wind Holdings was another successful bidder. Three floating wind turbine demonstration projects are run by RWE, which also manages wind farms across Europe. The other parties, Copenhagen Infrastructure Partners, Invenergy, and Ocean Winds, have leases on the Atlantic Coast or operate offshore wind farms.

Although floating offshore wind farms are a growing industry, there are still some technical issues that need to be resolved. Higher stresses on the tower and blades as well as more intricate and unstable aerodynamics may result from platform motion. Additionally, when sea depths increase, the cost of the mooring lines, anchors, and electrical cabling may increase, necessitating the need for less expensive yet still dependable technology.

Reference: The Conversation, techxplore.com