Using CarbonCure’s recovered water technique, which injects carbon dioxide (CO2) into concrete effluent, Heirloom, a developer of direct air capture (DAC) carbon removal, demonstrated the long-term storage of captured CO2 in concrete.

At a Central Concrete batch factory in San Jose, California, where the CO2-treated wastewater was used to manufacture fresh concrete for use in nearby construction projects, the captured gas was fed into the process wastewater. Even if the concrete is destroyed, the gas will not be released again into the atmosphere since it is successfully sequestered in the concrete as calcium carbonate.

Heirloom’s cyclic DAC method extracts CO2 from the atmosphere using limestone, and then heat from a renewable energy source breaks down the material creating calcium oxide rock and CO2 gas.

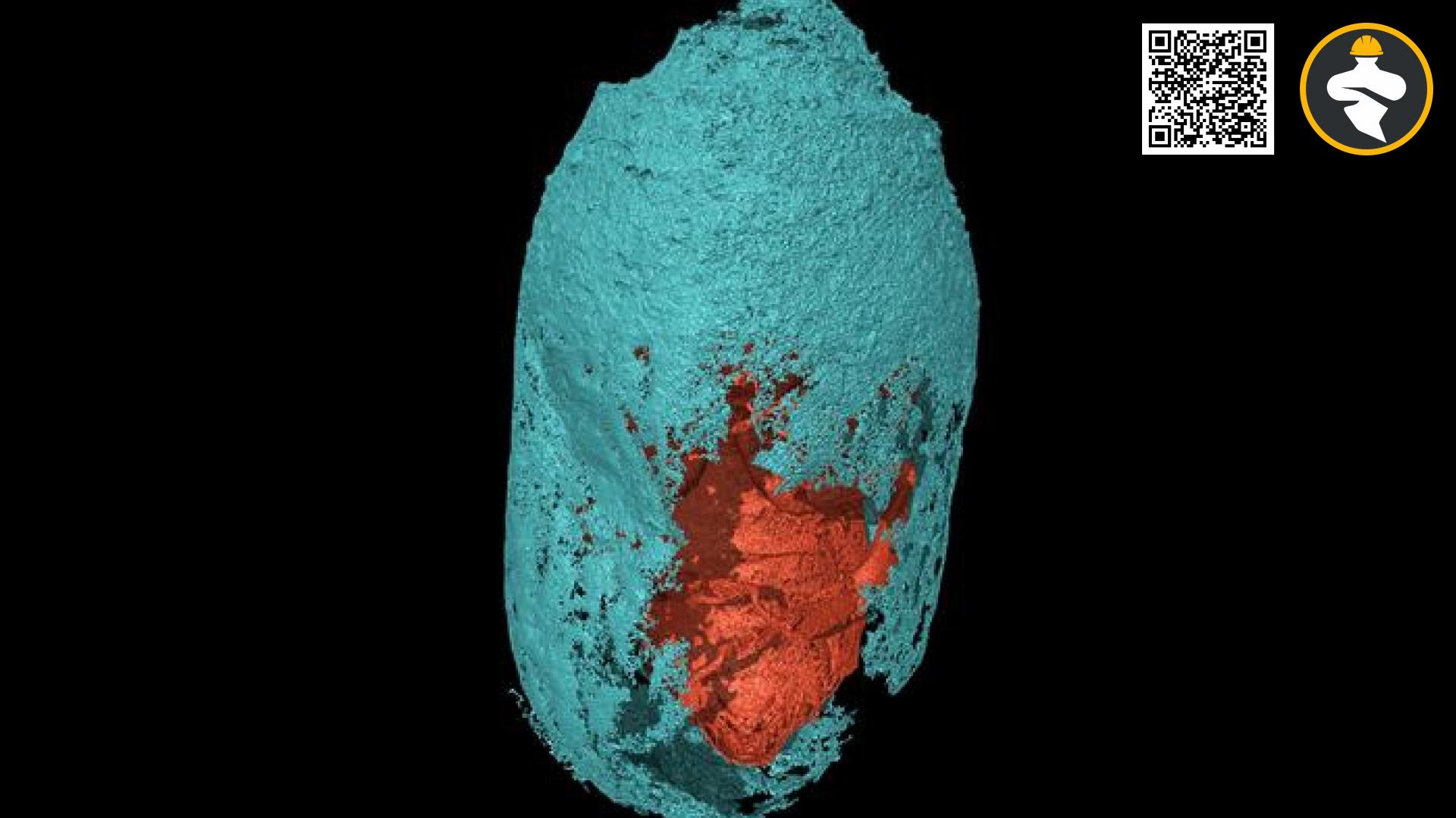

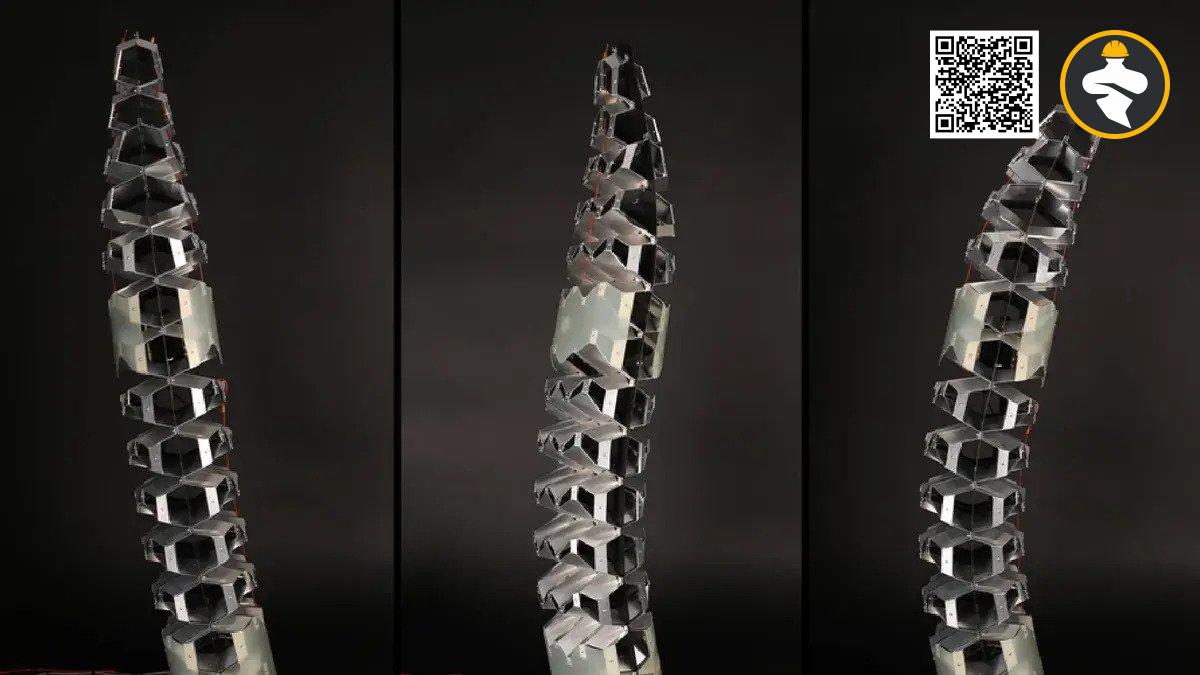

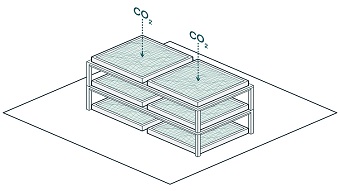

Vertically stacked trays of limestone mineral powder absorb carbon dioxide. Source: Heirloom

a power kiln. The calcium oxide is deposited onto trays that are stacked vertically, where it acts as a sponge to absorb CO2 before being put back in the kiln to continue the process. The gas is then securely permanently kept below or within concrete.

Injecting CO2 into recovered water at concrete plants is another aspect of the DAC-to-concrete solution that makes use of CarbonCure’s technology. Immediately after injection, the gas reacts with the cement in the water and mineralizes it, preserving it indefinitely and solidifying the cement for reuse. The new concrete mixes then contain the CO2-treated slurry. According to the company, its method can save up to 15% on virgin cement consumption, 20% on fresh water use, and 15 kg of CO2 for every cubic meter of concrete.

Reference: S. Himmelstein @globalspec.com