March 8 – Due to worries over fuel temperature, California-based firm Relativity Space postponed the planned debut launch of its 3D-printed rocket in Florida on Wednesday. This delayed a critical evaluation of the company’s innovative approach to reducing manufacturing costs.

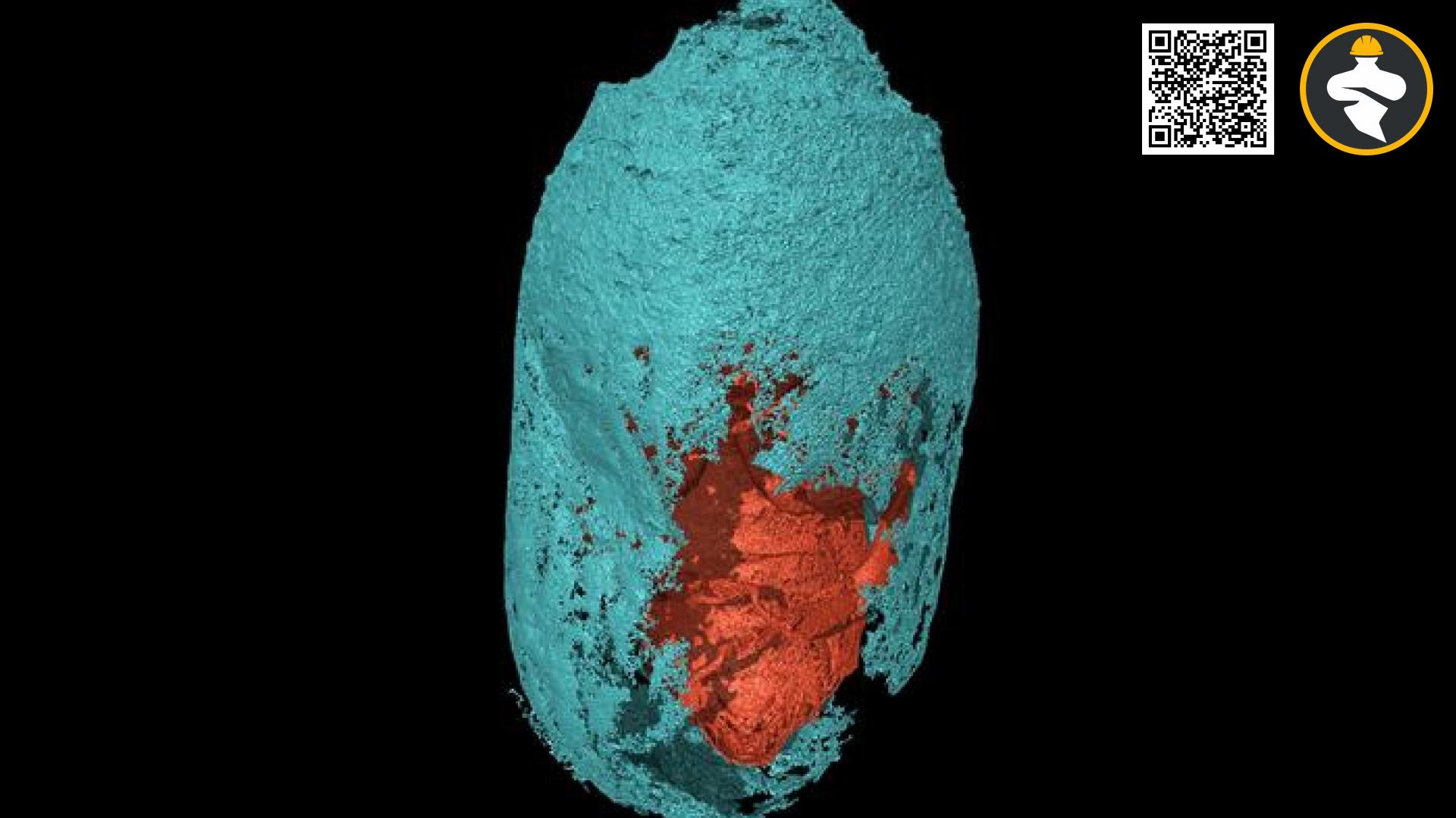

On Wednesday afternoon, the 110-foot-tall (35-meter) Terran 1 rocket—of which 85% was made using a 3D printer—was supposed to take off from a launch pad at the U.S. Space Force Base at Cape Canaveral. A scrub was ultimately necessary due to declining “propellant heat conditions” in the rocket’s second stage during a three-hour launch window, the firm announced on Twitter. The next attempt to launch the rocket is planned for Saturday within a window from 1 p.m. to 4 p.m. EST, according to the firm (1800 to 2100 GMT).

One of a few U.S. rocket firms, Relativity, has staked on the cost savings it anticipates from deploying massive, robotic 3D printers to streamline its rocket production lines. The company is competing to meet the growing demand for affordable launch services. Most of its competitors have concentrated on reducing costs by developing reusable rockets, such the Falcon 9 boosters made by Elon Musk’s SpaceX.

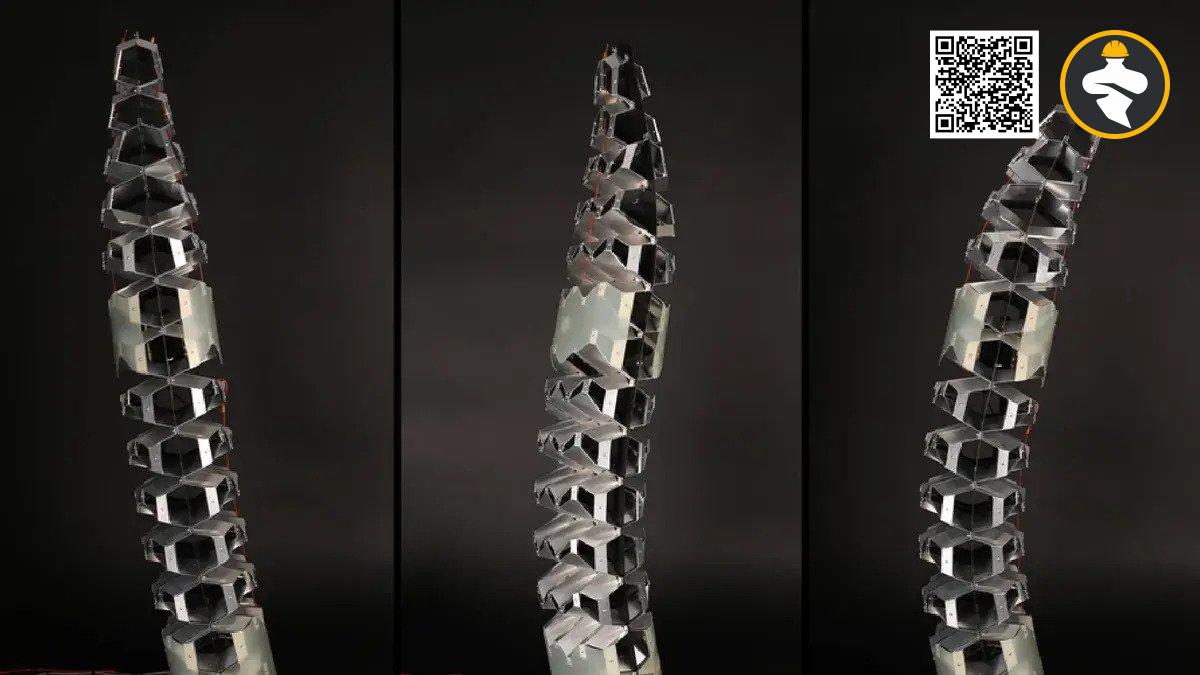

The business hopes that the Terran 1 launch will prove that its rocket’s 3D-printed construction can endure the rigors of an Earth launch. “The launch that we’re preparing for is an opportunity to demonstrate a whole lot of things all at once,” Josh Brost, Relativity’s senior vice president of revenue, told Reuters ahead of the planned launch attempt. The Terran 1 is “by far the largest 3D-printed structure that has ever been built,” according to Brost.

With the help of machines that autonomously “print” successive layers of soft, liquid, or powdered materials that are soon solidified or fused to form solid, three-dimensional things, 3D printing is a technology that is widely employed in many different industries. The blueprints for the artifacts’ designs are digitally digitized. According to Brost, Relativity’s use of 3D printers enables it to speed up many of its manufacturing procedures and more easily make changes to the rocket’s design if necessary after it has taken off. This eliminates the need for a convoluted supply chain that would otherwise slow down rocket improvements.

According to Brost, first launches of new rockets are notoriously prone to require a scrub for a variety of reasons. So, it would not be improbable for us to require a few tries to complete the countdown and launch for our first launch. Relativity has developed a larger, 3D-printed reusable rocket called the Terran R that it hopes to launch in 2024, despite the expendable Terran 1 being designed to lift 2,755 pounds (1,250 kg) of satellites into low-Earth orbit.

The so-called mega-constellation plans by businesses like SpaceX, OneWeb, and Jeff Bezos’ Amazon (AMZN.O) to launch tens of thousands of internet-beaming satellites into low-Earth orbit over the next five years are now fueling demand. Amazon and OneWeb intend to employ comparable huge rockets from other launch companies for their own satellites, while SpaceX currently launches its own heavy-lift rockets to place its Starlink network in orbit. The firms stated last year that OneWeb would use Relativity’s Terran R to launch its newest satellites.

For both of its rockets, Relativity has launch contracts worth approximately $1.65 billion, with the larger Terran R accounting for the majority of that money. Although there is less need for rockets like Terran 1 on the market, Brost asserted that Terran R will benefit from learning from Terran 1’s impending flights. Brost responded that Relativity “continues to talk to individuals about both cars” when asked if it is still selling Terran 1 to clients.

Reference: Reuters