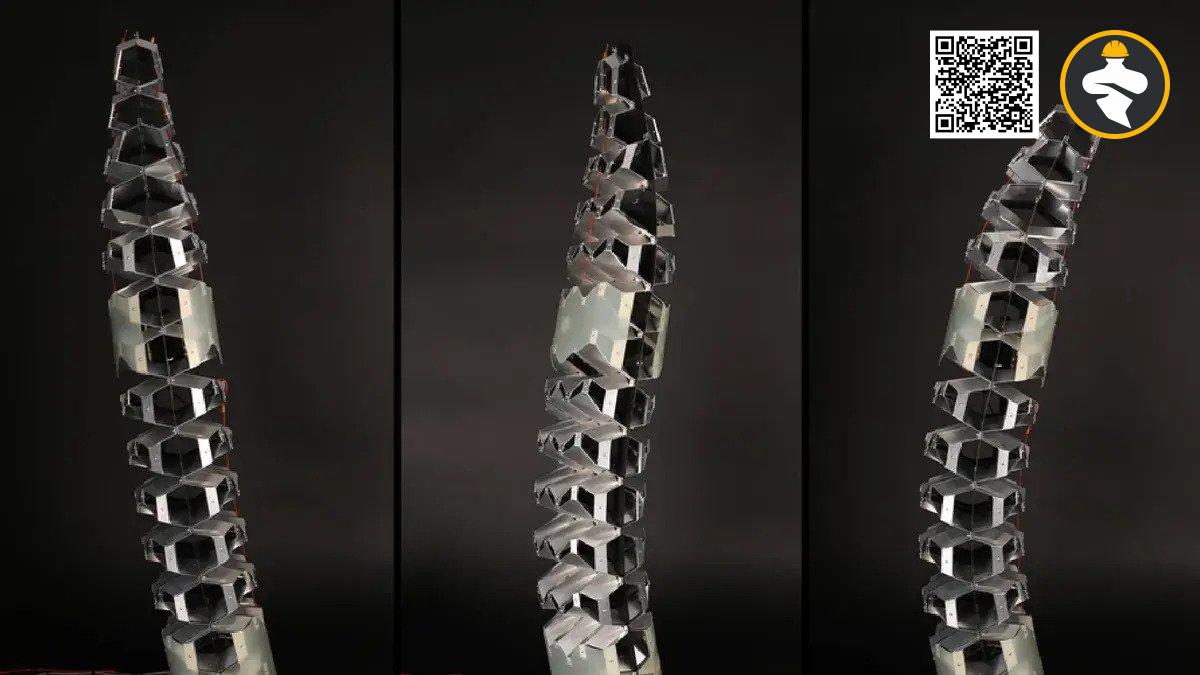

True shapeshifters include programmable materials. Pushing a button allows them to change their traits in a controlled and reversible manner, individually adapting to different situations. For instance, they can be employed to create comfortable chairs or bedsores-preventing mattresses. In order to create these, the support is designed with a vast contact surface, which reduces pressure on various body areas.

Researchers at the Fraunhofer Cluster of Excellence Programmable Materials CPM are creating this kind of programmable material, and they intend to market it with the aid of business partners. Reducing the consumption of resources is one of their objectives.

Whether due to disease, an accident, or old age, a large number of people around the world are bedridden. Those who are affected frequently develop excruciating bedsores since they are unable to move or turn over on their own. With the use of materials that can be programmed to completely modify their form and mechanical properties, bedsores should be preventable in the future.

The body support of mattresses constructed of programmable materials, for instance, can be changed at any location by pressing a button. Furthermore, the support layer is designed so that intense pressure applied to one spot can be dispersed over a larger region. Pressure-sensitive areas of the bed are naturally made softer and more elastic. The ergonomic laying posture can also be altered by caregivers to suit each patient.

Materials and microstructuring

Researchers from Fraunhofer CPM, which consists of six core institutes, are working to design and produce programmable materials for applications that call for specific changes in stiffness or shape. How do we program materials then?

According to Dr. Heiko Andrä, a spokesperson for the Fraunhofer Institute for Industrial Mathematics ITWM, one of the Fraunhofer CPM core institutes, “basically, there are two key areas where adjustments can be made: the base material—thermoplastic polymers in the case of mattresses and metallic alloys for other applications, including shape memory alloys.

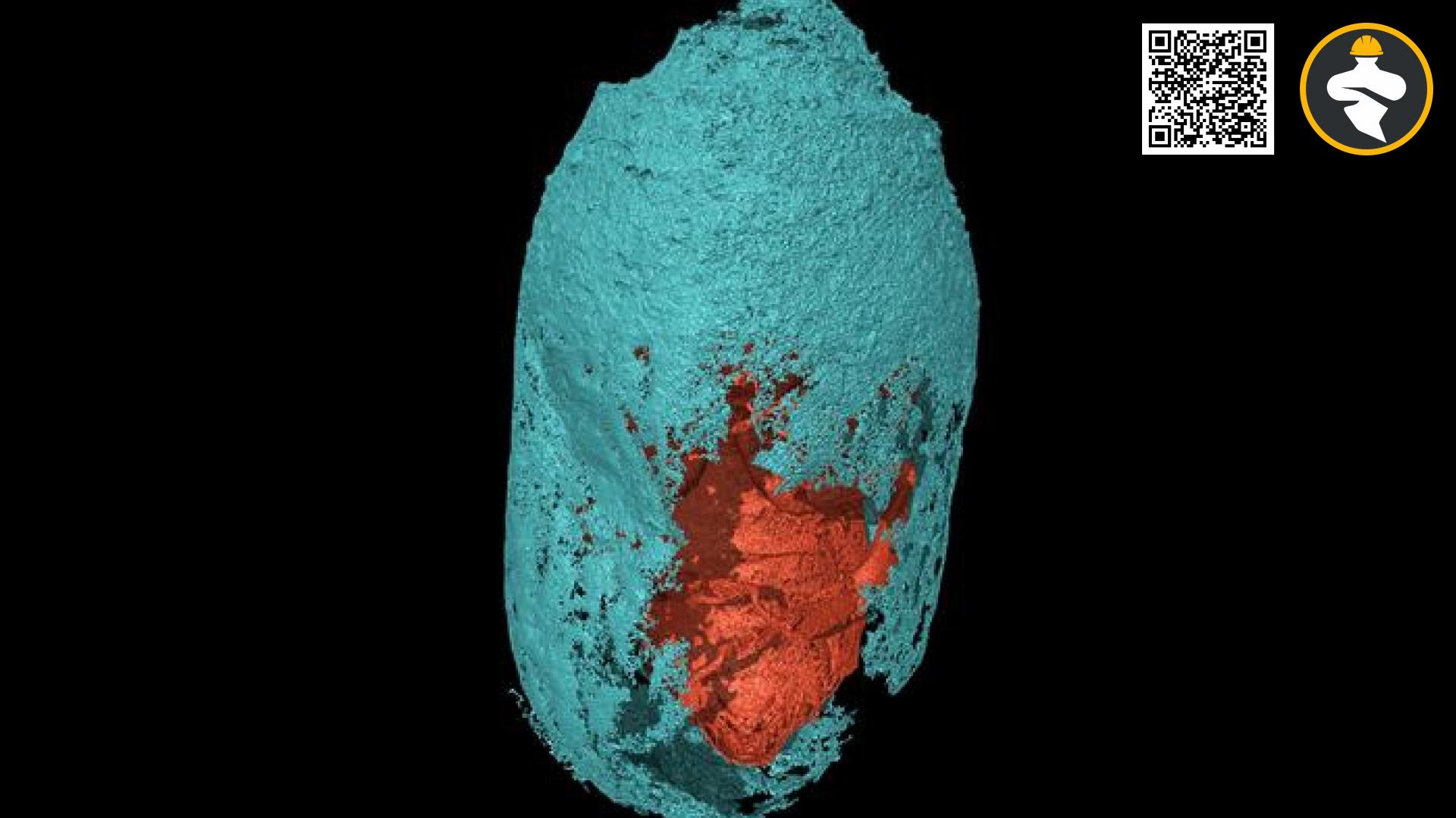

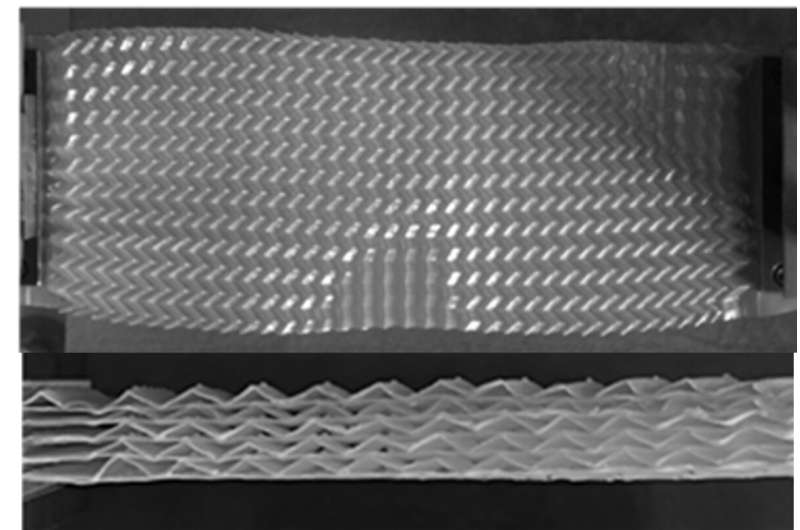

These metamaterials’ unit cells, which include structural components like tiny beams and thin shells, make up its microstructure. Unlike typical cellular materials like foams, where the size of each unit cell and its structural components varies randomly, programmable materials’ cells can be precisely defined, or programmed.

This programming can be set up, for instance, so that pressure applied to one area of the mattress would cause precise changes in other areas of the mattress, thereby expanding the contact surface and giving particular body parts the best support possible.

Materials can also react to temperature or humidity

The choice of material and its microstructure can influence the form change that the material should experience as well as the stimuli to which it reacts, such as mechanical stress, heat, moisture, or even an electric or magnetic field.

“Products can now be customized to a specific application or user, making them more multipurpose than in the past. As a result, they don’t need to be changed as frequently. In terms of sustainability and the conservation of resources, it is especially intriguing “Franziska Wenz, a representative for the Fraunhofer Institute for Mechanics of Materials IWM, a core organization of Fraunhofer CPM, makes this claim. When items are tailored to the unique requirements of the users, this can also provide value.

The journey to application

The function of complete systems of sensors, regulators, and actuators can be replaced by a single piece of material. By integrating their functionality into the material and decreasing material diversity, Fraunhofer CPM seeks to simplify systems. “We always design programmable materials with industrial products in mind. Consequently, we consider mass manufacturing techniques and material fatigue, among other factors “Wenz states.

With industrial partners, the initial pilot projects have already begun. The research team anticipates that initially, programmable materials would function as upgrades for parts in already-existing systems or be utilized in unique applications like medical beds, cozy seats, variable-damping shoe bottoms, and protective apparel. According to Andrä, the use of programmable materials will rise gradually. In the end, they can be applied everywhere, from soft robotics and space exploration to health and sporting products.

Reference: Provided by Fraunhofer-Gesellschaft, Ilka Blauth @ techxplore.com