John Deere’s parts distribution center in Campinas, Brazil, has implemented Comau’s MATE XT wearable exoskeleton to support ergonomic well-being among its employees. The exoskeleton is designed to reduce the risk of injury and fatigue associated with repetitive movements and heavy lifting.

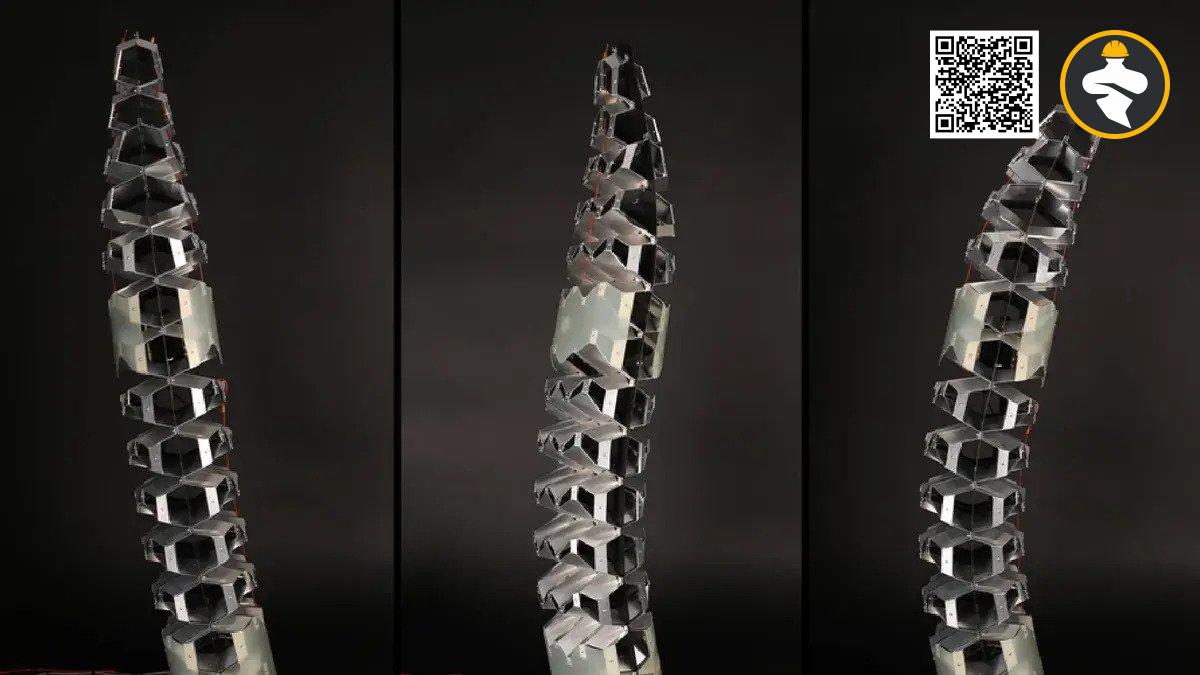

The MATE XT is a lightweight exoskeleton that can be worn like a backpack. It is designed to support the upper body and arms, reducing the strain on the shoulders, neck, and back. The exoskeleton is made of carbon fiber and aluminum and weighs just 3.5 kilograms.

Source: Comau

The MATE XT is equipped with a variety of sensors that monitor the user’s movements and provide real-time feedback. This allows the exoskeleton to adjust its level of support based on the user’s needs. The exoskeleton also features a battery pack that provides up to eight hours of continuous use.

The implementation of the MATE XT at John Deere’s parts distribution center has been successful so far. Employees who have used the exoskeleton report feeling less fatigued and experiencing fewer aches and pains. The exoskeleton has also helped to reduce the risk of injury associated with heavy lifting.

Overall, the MATE XT wearable exoskeleton is a promising technology for improving ergonomic well-being in the workplace. As more companies adopt this technology, we can expect to see a reduction in workplace injuries and an improvement in employee well-being.

Reference: GlobalSpec