Ice. It’s an annoying side effect of life as it’s practiced in many cultures. Ice continues to pose a problem as much of the world is still mired in winter, having an effect on a range of surfaces including solar panels, planes, and roads.

For instance, ice buildup on airplane wings reduces lift, increases drag, and potentially jeopardizes the aircraft’s safety. Ice can also result in flight delays and cancellations, which wastes time and money. The same is true for icy roads, which are dangerous for motorists. On the other hand, ice buildup on solar panels can harm their surfaces and reduce energy output.

The developments listed below are being used to produce anti-icing or deicing technologies that influence surfaces in the transportation and energy sectors.

Laser ice repellent

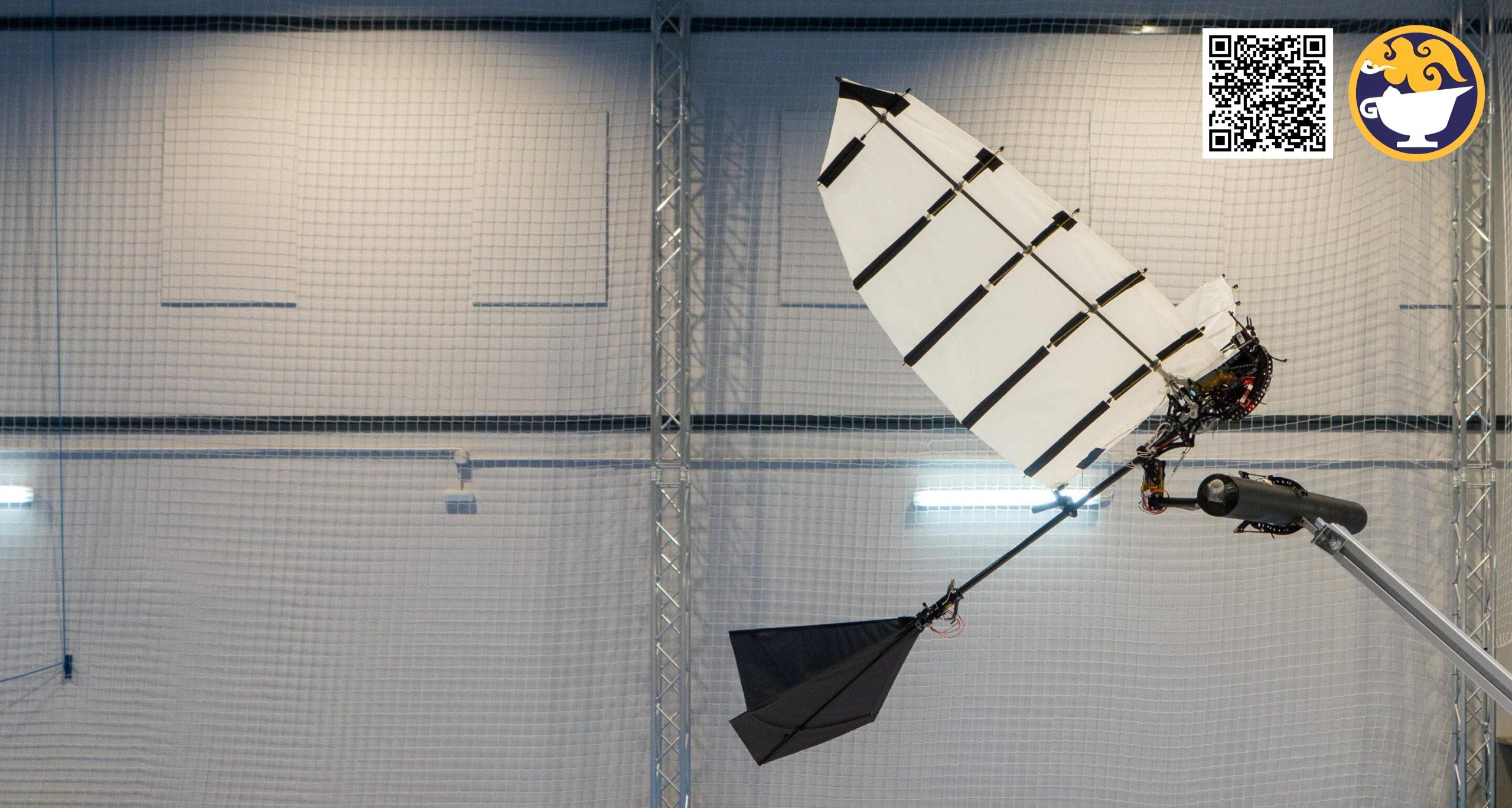

Direct laser interference patterning (DLIP) technology is being used by researchers from the Fraunhofer Institute for Material and Beam Technology, Airbus, and the Dresden University of Technology to etch 3D microscale shapes into airplane wings in an effort to reduce the buildup of ice.

The airfoil with the water-repellent structured surface. Source: Airbus

The team processes up to one sq m of material every minute using short and ultrashort pulse lasers to create surface structures. According to the manufacturer, the final surface with fragments removes ice’s attachment sites.

De-ice coating

Researchers from the University of Illinois at Chicago (UIC) have created a de-icing coating that is pending patent protection that keeps ice from building up on aircraft surfaces. The coating’s creators claim that it is based on a recipe that uses modern de-icing agents.

The researchers said, “We questioned the cryoprotectants’ longevity and looked at novel approaches to enhance their efficacy. “Glycols disintegrate very quickly in the water and are washed away prior to takeoff. This is a huge issue that costs hundreds of millions of dollars, the majority of which literally goes down the drain. Why not produce alternatives that are more environmentally friendly and can endure longer than such chemicals, we reasoned. And that’s what we ultimately did.

The researchers used this information to create a family of more than 80 anti-freezing coatings that may be used on a variety of surfaces, including aluminum, glass, steel, copper, plastic, and other industrial surfaces. The coating, according to the company, can simply shed off any ice that does eventually accumulate after delaying the formation of frost on such surfaces for hours.

The researchers contend that because the UIC coating lasts longer than conventional de-icing chemicals, its usage on aviation wings would reduce chemical runoff, which pollutes freshwaters. Despite the fact that these chemicals work to de-ice the wings, once the plane takes off, they disperse and run off into the ground or water below it, leaving the wings open to re-icing.

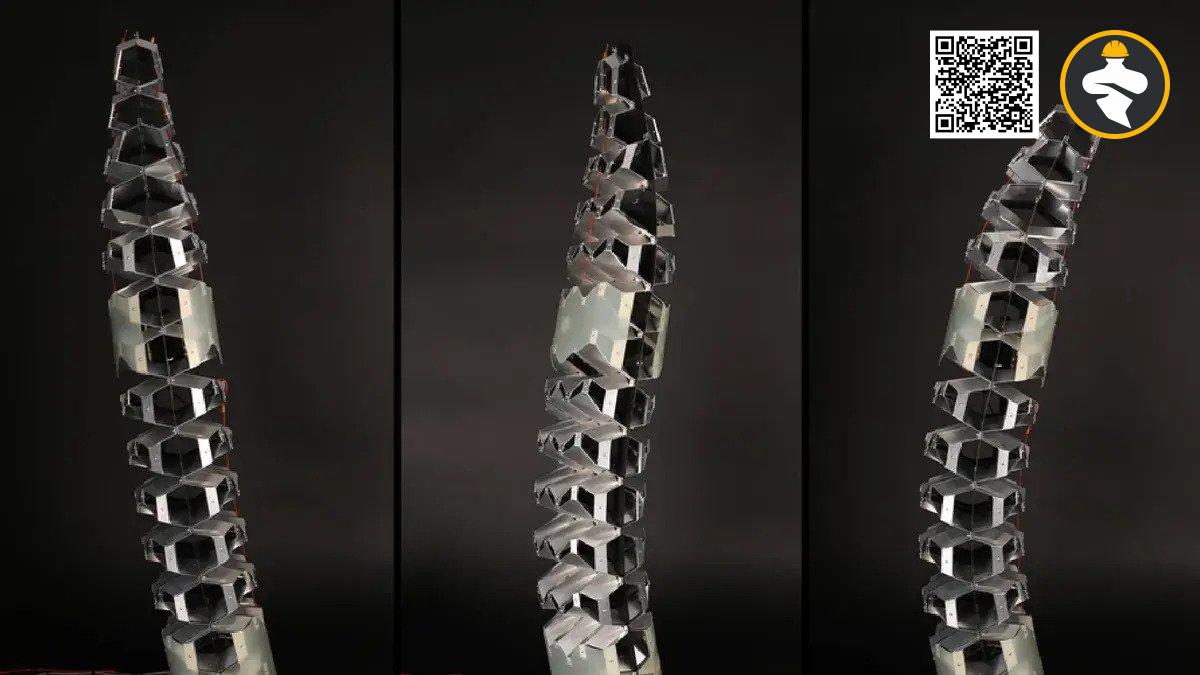

Aluminum pillars

Researchers from Virginia Polytechnic Institute and State University and the University of California have created a water-repellent surface to stop this from happening since ice that has been removed from an airplane wing can regrow after departure.

Instead of typically used chemical treatments, the newly developed water-repellent surface uses millimeter-sized aluminum pillars. The researchers claim that as frost develops on top of the aluminum pillars, minute ice bridges are subsequently made, trapping air pockets beneath. As a result, the ice sheet is suspended by the trapped air pockets, which lessens the ice’s surface adherence.

Source: Stephan HerbLeaf geometry

Researchers at Northwestern University have created a technique for reducing the production of ice on surfaces like airplane wings that is inspired by the geometry of leaves. The researchers found that altering the texture of surfaces was essential to lowering frost development, which was reported to be reduced by 60% in the study. They recognized that convex characteristics of leaves tend to promote more frost formation than concave aspects.

According to studies, surfaces with peaks and valleys, like a leaf, deter the growth of frost because condensation is promoted on the peaks and restrained in the valleys of the leaf. According to the research, some of the condensed water that gathers in the valleys apparently evaporates. As a result, when the temperature dips below freezing, those components are essentially frost free.

The researchers discovered that surfaces with millimeter-sized peaks and valleys and angles in the 40° to 60° range worked best to establish the optimal geometry of peaks and valleys on a surface to prevent frost formation. During testing, frost still developed on surface peaks when the temperature dropped below freezing, but it was removed with a lot less energy than was previously needed to do so for a flat surface.

Sprayable coating

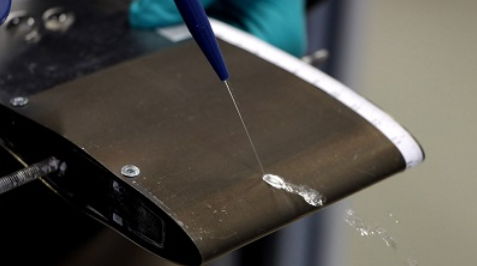

To stop ice from forming on airplane wings, engineers at the University of Houston have created a sprayable ice-shedding coating. The coating is described by the University of Houston study team as a “fracture-controlled surface,” which implies that it is 100 times stronger than all coatings that are currently being developed and sold.

According to reports, the coating obtained its name by using different chemical and mechanical compositions to promote fracture formation at the interface, divert energy toward those cracks, and so accelerate their propagation.

“We created a brand-new idea in which you can simply remove foreign things from the surface and greatly speed up crack creation and growth through material design. This idea is put into practice to create materials that are extremely resilient and don’t stick to ice. Fracture-controlled surfaces offer a rich platform for future material development of materials with low adhesion and great durability, “researchers from the University of Houston noted.

The coating’s three phases—the matrix phase, the phase for guiding crack propagation, and the phase for crack formation—successfully avoid the hazardous buildup of ice on airplane wings.

The coating, according to the researchers, is based on the idea that removal of external solid objects from surfaces requires the application of force, which promotes the growth of fractures at the contact. The ice completely separates from the surface as the cracks quickly spread as they start to appear.

Moth eyes

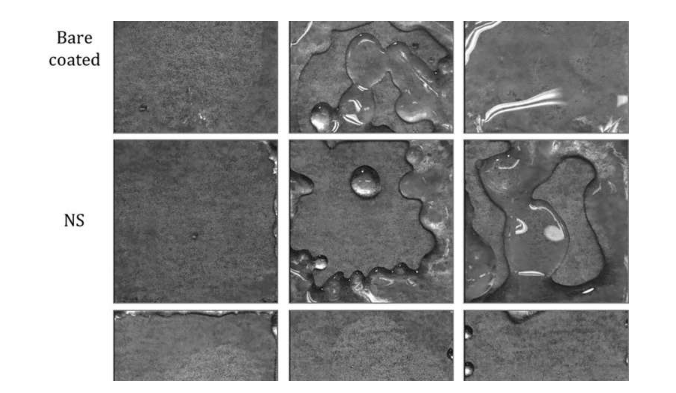

A transparent anti-icing nanostructure created by researchers from Tan Trao University and Thai Nguyen University of Education in Vietnam was inspired by the eyes of moths. The nanostructure was constructed on a quartz substrate and covered in a layer of paraffin wax, which is both water- and heat-resistant.

Ice accumulation on a bare coated, nanostructure (NS) and nanostructure covered in paraffin (NSP) samples after a freezing test. Source: Nguyen Ba Duc

The capacity of the material to reject water and its heat-delayed design allowed researchers to simulate the anti-icing properties of moth’s eyes during testing, stopping the icing process during water droplet and freezing rain experiments. The air blocks entrapped within the nanostructure also hindered heat transfer, lengthening the freezing periods of the associated water droplets. Researchers believe that the substance may have use for airplane wings that, if frozen over, might result in terrible accidents.

Reference: Marie Donlon @ globalspec